How to Stop Engine Knock & Why It Matters

Engine knock, also known as detonation or spark knock, is a common issue that can lead to significant engine damage if not addressed promptly. Understanding what engine knock is, its causes, and how to prevent it is crucial for maintaining the health and performance of any vehicle.

What Is Engine Knock?

Engine knock occurs when the air-fuel mixture in a gasoline engine ignites prematurely, leading to a knocking or pinging sound. Instead of a smooth combustion process, the fuel ignites at an unintended time, creating excessive pressure in the combustion chamber. This abnormal combustion can damage engine components, such as pistons, cylinder heads, and bearings.

Distinguishing Engine Knock from Normal Engine Sounds

Detecting engine knock is typically done through auditory cues and engine performance observations. Here are some signs to watch for:

- Knocking or Pinging Sound: The most noticeable indicator of engine knock is a metallic knocking or pinging noise, especially under acceleration or high load conditions.

- Loss of Power: A noticeable decrease in engine power or acceleration can indicate that the engine is experiencing knocking.

- Poor Fuel Economy: If the vehicle's fuel efficiency suddenly decreases, it may be due to engine knock affecting performance.

- Check Engine Light: In some cases, the vehicle’s onboard diagnostic system may detect engine knock and trigger the check engine light.

Common Causes of Engine Knock

- Low-Quality Fuel: The octane rating of fuel significantly impacts its resistance to knocking. Fuels with lower octane ratings are more prone to premature ignition, making them a common cause of engine knock.

- Improper Timing: When ignition timing is set too advanced, it can cause the air-fuel mixture to ignite too early, leading to knocking.

- Overheating: High combustion temperatures can trigger engine knock. An overheated engine may result from cooling system failures or low coolant levels.

- Carbon Buildup: Accumulation of carbon deposits in the combustion chamber can create hot spots that ignite the air-fuel mixture prematurely, contributing to knocking.

- Lean Air-Fuel Mixture: A mixture that has too little fuel (lean) can elevate combustion temperatures, increasing the likelihood of engine knock.

Preventative Measures

Use High-Quality Fuel

Always choose fuel with the appropriate octane rating as recommended in the vehicle’s owner’s manual. Higher octane fuels are formulated to resist knocking due to their ability to withstand greater pressure before igniting. This characteristic is especially important for vehicles with high compression engines or those equipped with turbochargers. Using high-quality fuel can enhance engine performance, improve efficiency, and extend the life of engine components by minimizing the risk of knocking.

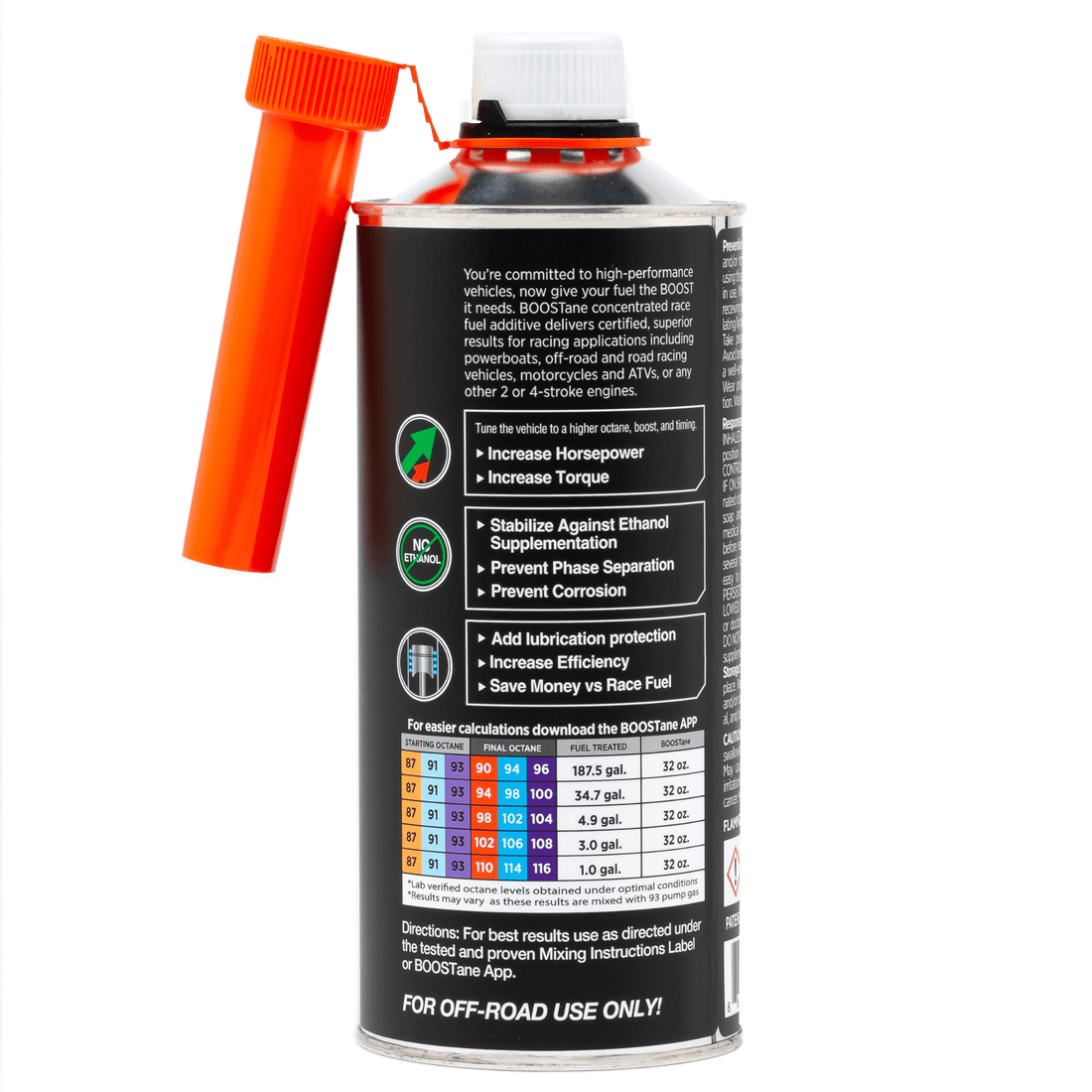

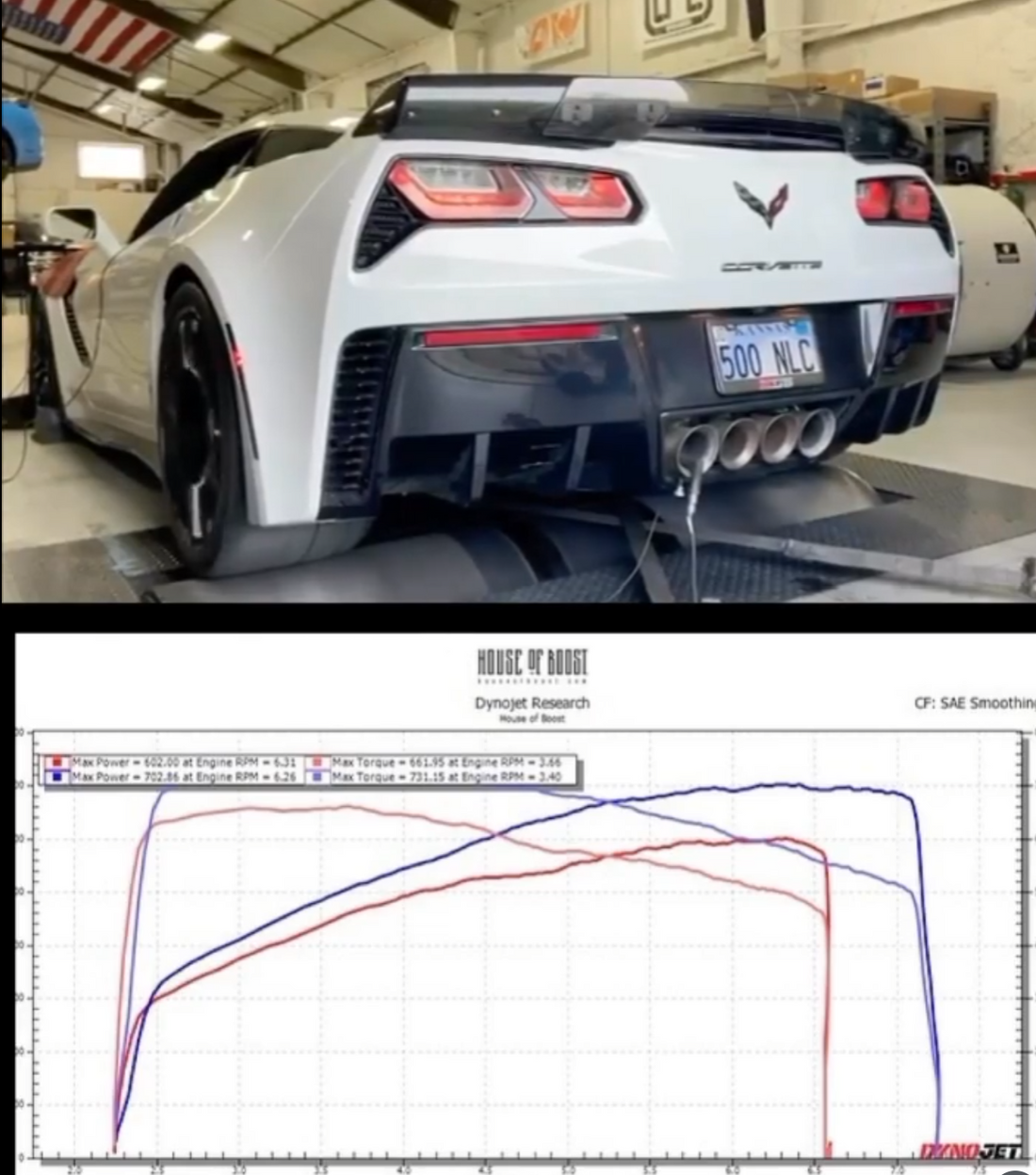

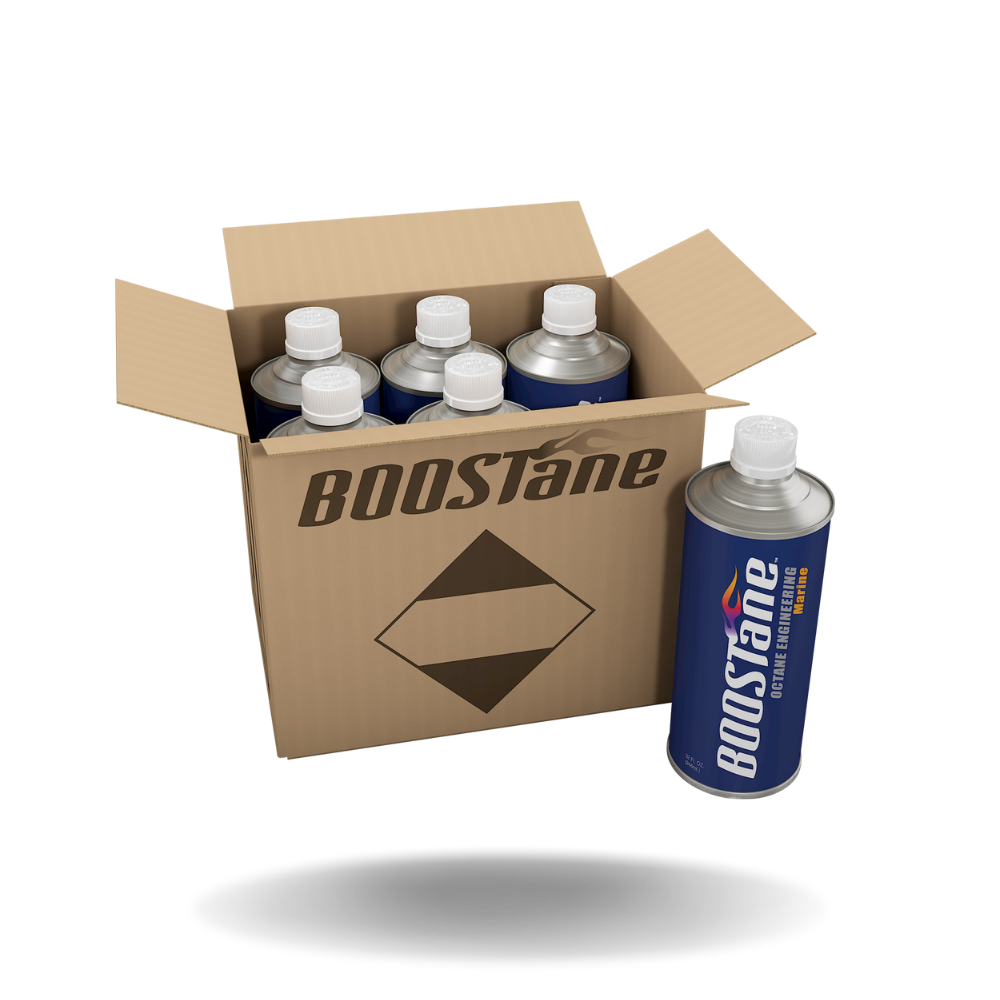

Use an Octane Booster

If higher-octane fuel is unavailable, consider using a quality octane booster, as many do not work. These additives are specifically designed to increase the octane rating of your fuel, enhancing its resistance to premature ignition. They work by modifying the combustion characteristics of the fuel, helping to prevent knocking in high-performance vehicles or older engines that may be more susceptible to this issue.

When selecting an octane booster, choose a reputable brand and follow the manufacturer’s instructions for dosage and application. It's important to note that while octane boosters can effectively improve performance and reduce knocking, they should not replace high-octane fuel when it is available. Using an octane booster as a regular practice can also be beneficial in maintaining optimal engine health, especially in demanding driving conditions.

Regular Maintenance

Routine maintenance is vital for optimal engine performance and longevity, playing a crucial role in preventing engine knock. This includes regular oil changes, which ensure that engine components are lubricated properly and can operate efficiently. Replacing spark plugs at recommended intervals is also essential, as worn or fouled plugs can lead to misfires and improper ignition timing, contributing to knocking.

Additionally, regularly checking and replacing air filters helps maintain proper airflow to the engine, ensuring that the air-fuel mixture remains balanced. Following the manufacturer's maintenance schedule can significantly reduce the likelihood of engine knock and other related issues.

Check Timing Settings

Having a professional mechanic inspect and adjust ignition timing is crucial for preventing engine knock. Ignition timing refers to the precise moment when the spark plug ignites the air-fuel mixture in the combustion chamber. If the timing is set too advanced, it can cause the fuel to ignite prematurely, leading to knocking. Conversely, if the timing is too retarded, it can result in poor engine performance. Regularly checking and adjusting the timing settings as needed can help ensure that the engine runs smoothly and efficiently, reducing the risk of knocking.

Monitor Engine Temperature

Keeping an eye on the engine temperature gauge is vital for preventing engine knock. An overheated engine can create conditions conducive to knocking, as elevated temperatures increase combustion pressure. Factors that contribute to overheating may include a malfunctioning thermostat, a failing water pump, or low coolant levels. If the engine runs hotter than normal, it’s important to diagnose the underlying cause promptly. Regularly checking coolant levels and ensuring the cooling system is functioning properly can help maintain optimal engine temperatures and prevent knocking.

Clean Carbon Deposits

Over time, carbon deposits can accumulate in the combustion chamber, leading to hot spots that ignite the air-fuel mixture prematurely. Using fuel additives designed to clean carbon deposits can help maintain a clean combustion chamber and reduce the likelihood of knocking.

These additives can break down existing deposits and prevent new ones from forming. Performing regular engine decarbonization services can be beneficial, especially for older vehicles or those that frequently experience knocking. Keeping the engine clean ensures optimal performance and reduces the chances of knocking.

Adjust Fuel Mixture

For vehicles with adjustable fuel settings, ensuring the correct air-fuel mixture is critical for optimal performance and knock prevention. A mixture that is too lean (too much air and not enough fuel) can elevate combustion temperatures, increasing the likelihood of knocking.

A mixture that is too rich (too much fuel and not enough air) can lead to poor combustion efficiency. Regularly checking and adjusting the fuel mixture, especially after modifications or repairs, helps ensure that the engine operates within its optimal range, reducing the risk of knocking and enhancing overall performance.

Conclusion

Engine knock is a serious issue that can compromise vehicle performance and longevity. By understanding its causes and implementing preventive measures, vehicle owners can significantly reduce the risk of knocking and ensure their engines operate smoothly and efficiently. Regular maintenance and attention to fuel quality are essential steps in maintaining engine health.